In the rapidly evolving world of electronics, the demand for efficient and precise testing tools is more significant than ever. Engineers, hobbyists, and manufacturers alike are constantly on the lookout for advanced devices that can streamline their work, provide accurate data, and integrate seamlessly into their workflows. Among the numerous tools and technologies available, certain standouts have become indispensable in the field.

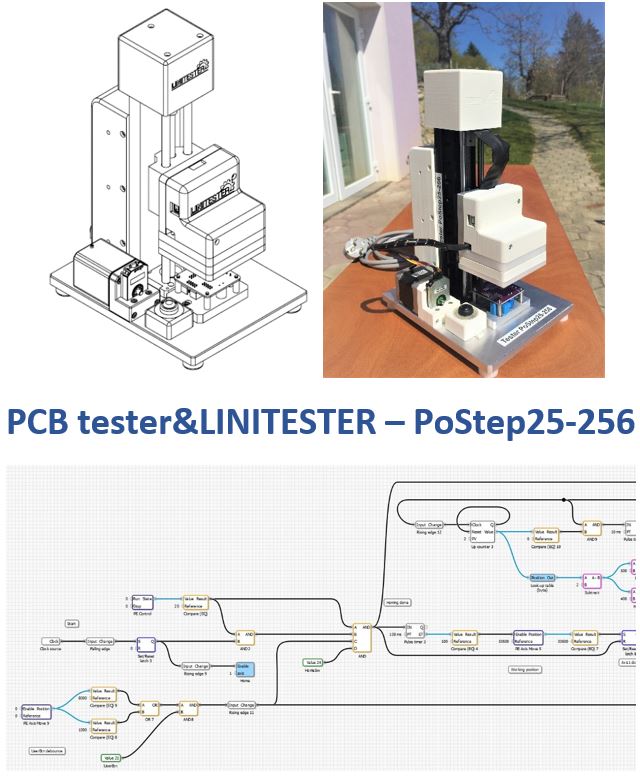

This article focuses on four key aspects of modern electronics testing and debugging. At the heart of our discussion is the PoStep25-256, a versatile motion control module that is revolutionizing the way we manage motorized systems. Around this central topic, we will explore complementary tools and techniques that enhance its application: the PCB tester, essential for ensuring the quality of circuit boards; the USB oscilloscope, a compact yet powerful diagnostic device; and the art of decoding I2C protocols, which bridges the gap between digital communication and effective problem-solving.

By diving into these interconnected subjects, we aim to shed light on how they work together to simplify and improve the process of designing and testing modern electronics. Whether you’re a seasoned engineer or an enthusiastic tinkerer, understanding these tools can significantly elevate your projects and provide new insights into the exciting world of electronics.

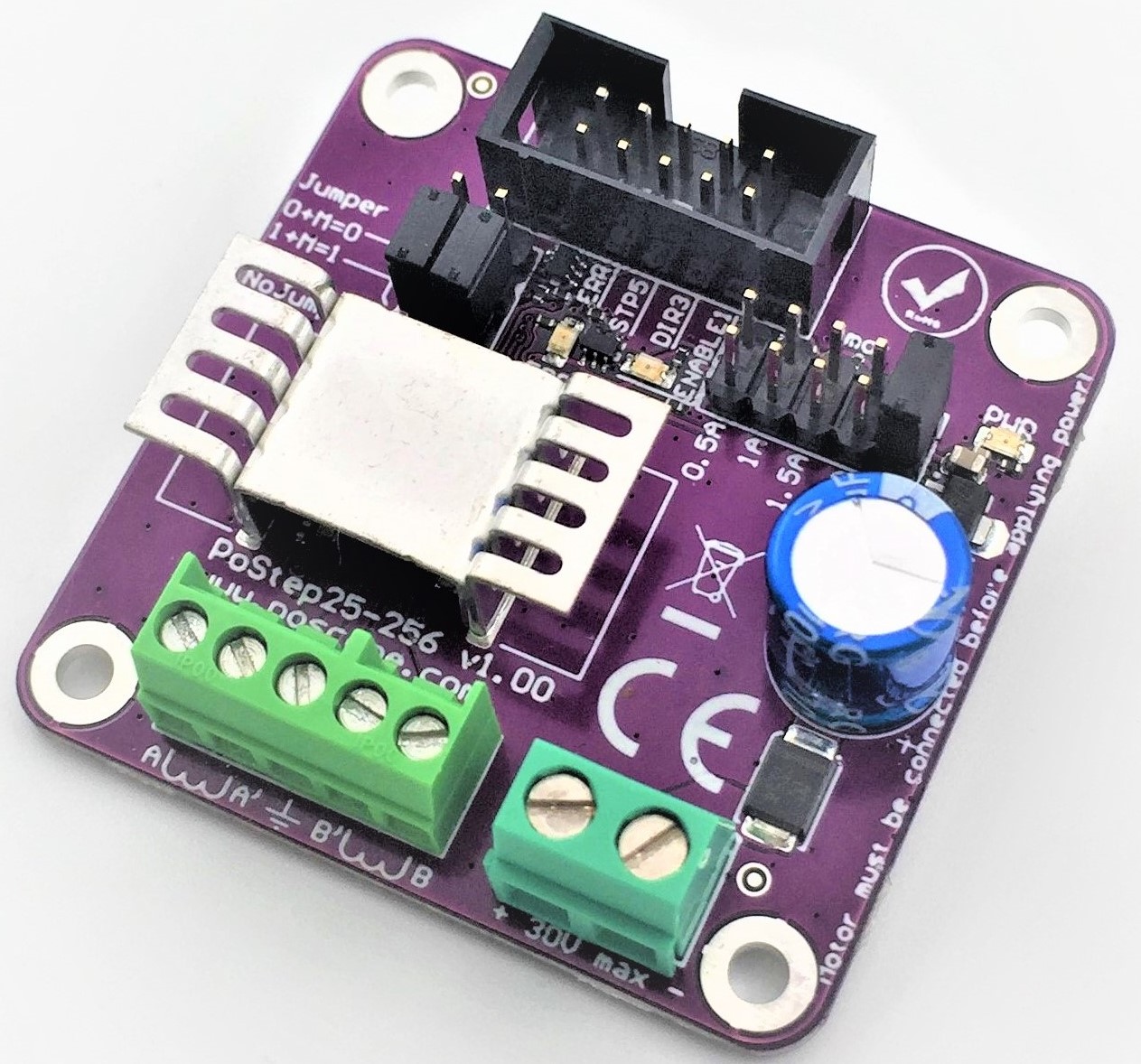

PoStep25-256: Revolutionizing Motion Control in Electronics

In the realm of modern electronics, efficient motion control is essential for a wide variety of applications, from robotics and automation to precision machinery. At the core of this technology is the PoStep25-256, a sophisticated stepper motor driver designed to provide both power and precision in motion control systems. As one of the most advanced motion controllers available today, the PoStep25-256 offers a comprehensive solution to some of the most pressing challenges in motor control: accuracy, stability, and efficiency.

The PoStep25-256 is part of a family of stepper motor drivers developed by the company Pololu, and it is built around a robust and versatile chipset. Its design focuses on providing high-performance control over stepper motors, which are widely used for applications requiring precise position control. Whether in 3D printers, CNC machines, or industrial automation, stepper motors enable exact movement based on electrical pulses. The PoStep25-256 is engineered to drive these motors with superior accuracy, allowing for precise adjustments and smooth operation even in high-demand environments.

What sets the PoStep25-256 apart from its predecessors is its advanced microstepping capabilities. Microstepping is a technique that divides each step of the motor into smaller increments, offering finer control and reduced vibration. This feature is particularly useful in applications that require high precision, such as in robotics or precise positioning systems. The PoStep25-256 allows users to configure up to 256 microsteps per full step, offering a level of fine-tuning that most traditional stepper motor drivers simply can’t match. As a result, users can achieve smoother and more refined motion control, enhancing the overall performance of their projects.

Another key feature of the PoStep25-256 is its built-in current regulation. This feature ensures that the stepper motor receives a consistent and stable current, which is critical for preventing overheating and reducing wear and tear on the motor. By maintaining an optimal current level, the PoStep25-256 maximizes the motor’s efficiency while minimizing the risk of damage. This is especially important in systems that require prolonged or continuous operation, where motor failure can lead to significant downtime and costly repairs.

Additionally, the PoStep25-256 offers a range of safety features designed to protect both the motor and the system as a whole. For example, it has built-in overcurrent protection, thermal shutdown, and undervoltage lockout, all of which ensure that the motor is operating within safe parameters. These features make the PoStep25-256 a reliable and durable solution for a wide range of industrial and consumer-grade applications.

The versatility of the PoStep25-256 extends beyond its performance capabilities. It is designed to be easy to integrate into various systems, with simple control inputs such as step, direction, and enable pins. This makes it an ideal choice for users who need a plug-and-play solution that doesn’t require extensive configuration. Furthermore, the PoStep25-256 is compatible with a wide range of microcontrollers and development platforms, including Arduino, Raspberry Pi, and other common embedded systems. This broad compatibility means that developers can easily incorporate the PoStep25-256 into their existing workflows, making it an attractive option for both beginners and experienced engineers alike.

One of the standout applications of the PoStep25-256 is in 3D printing, where precise control of the stepper motors is critical to ensure the accurate deposition of material. In 3D printers, the PoStep25-256 can help achieve smoother movement of the print head, reducing artifacts such as layer misalignment or print defects. In fact, many 3D printing enthusiasts and professionals have embraced the PoStep25-256 for its ability to deliver better print quality and reliability compared to standard motor drivers.

Industrial automation is another area where the PoStep25-256 shines. Whether in automated assembly lines, robotic arms, or conveyor systems, this motion controller provides the accuracy and robustness needed to maintain smooth, continuous operations. Its ability to handle high current loads and support fine-tuned control means that it can operate in environments where other drivers might struggle, making it a preferred choice for industrial-grade systems.

Despite its advanced features, the PoStep25-256 is not just limited to complex industrial applications. Its ease of use and reliability make it a valuable tool for hobbyists and DIY enthusiasts who want to build their own motion-controlled systems. Whether it’s for creating a robotic project, a motion-controlled camera system, or a custom CNC machine, the PoStep25-256 is an accessible and powerful option for anyone looking to enhance their electronics designs.

The integration of PoStep25-256 into a broader system often requires testing and tuning to ensure optimal performance. This is where tools such as PCB testers and USB oscilloscopes become invaluable. A PCB tester can help validate the integrity of the circuit board on which the PoStep25-256 is mounted, while a USB oscilloscope can allow for real-time monitoring of the electrical signals sent to the motor. These tools, when used in conjunction with the PoStep25-256, provide a comprehensive solution for troubleshooting and refining the motion control system.

Ultimately, the PoStep25-256 is more than just a stepper motor driver – it is a gateway to higher performance and greater precision in motion control. Whether you’re a professional engineer or a hobbyist, its versatility, safety features, and microstepping capabilities make it an invaluable tool in your electronics toolkit. As the demand for more precise and efficient motion control systems continues to grow, the PoStep25-256 will undoubtedly remain at the forefront of innovation in this space.

PCB Tester: Ensuring the Reliability of Your Circuits

In the world of electronics, a PCB tester is an indispensable tool used to ensure that printed circuit boards (PCBs) function as intended. A PCB tester is crucial in identifying faults, verifying connections, and validating the integrity of a PCB before it is integrated into a larger system. The importance of testing PCBs cannot be overstated, as even a small error can result in a system failure, leading to costly repairs or even complete device failure. This chapter explores the role of PCB testers in modern electronics, highlighting how they contribute to the overall success and reliability of electronic products.

A printed circuit board (PCB) serves as the backbone of most electronic devices, providing both mechanical support and electrical connectivity for components like resistors, capacitors, and integrated circuits. The design of a PCB is a delicate process that involves routing intricate traces to ensure the correct flow of electrical current and the proper placement of components. While design software can simulate circuit behavior, testing the actual PCB is essential to confirm that all traces are correctly laid out and that there are no unintended shorts, broken connections, or other issues that could impair the board’s performance.

A PCB tester is designed to detect these potential issues by testing the electrical connections of a finished PCB. Traditional testing methods include visual inspection, manual probing, and the use of multimeters, but these approaches can be time-consuming and prone to human error. A PCB tester, on the other hand, automates much of the testing process, allowing for more efficient and thorough testing.

One of the most common types of PCB testers is the in-circuit tester (ICT), which uses a series of probes to make contact with the test points on a PCB. These testers check the electrical integrity of the PCB by verifying that the traces connect properly between different components. The ICT can detect open circuits (broken traces), shorts (unintended connections between traces), and other common faults. More advanced versions of the PCB tester use boundary scan technology, which allows for testing without physically probing the PCB. This method works by using the JTAG (Joint Test Action Group) interface, which is built into many modern ICs and allows for testing by communicating directly with the chips on the PCB.

The primary benefit of using a PCB tester is the ability to quickly and accurately identify defects before the PCB is assembled into a more complex system. This can prevent the need for costly rework or troubleshooting later in the design process. By identifying faults early, designers can correct issues while the board is still in its early stages, ensuring that the final product is more reliable and functionally sound. This is especially important in industries where safety and performance are paramount, such as aerospace, automotive, and medical devices.

Another key advantage of using PCB testers is their ability to check for component placement errors. Sometimes, components can be incorrectly placed on a PCB, leading to short circuits or other malfunctions. A PCB tester can verify that components are installed in the correct orientation and that all pins are properly soldered to the board. This is particularly useful in high-density PCBs, where the layout can be complicated, and manual inspection may miss subtle errors.

In addition to testing for electrical faults, a PCB tester can also help assess the overall quality of the PCB. For instance, testers can check for continuity, resistance, capacitance, and other parameters that ensure the board meets the necessary specifications. These tests provide valuable insight into the board’s overall functionality, including the signal integrity of high-speed circuits. In some cases, PCB testers can also test for mechanical defects such as warping, cracking, or bending that could affect the board’s performance.

The integration of advanced technologies like USB oscilloscopes and PoStep25-256 drivers further enhances the power of PCB testers. For example, when testing the functionality of a motor-controlled system with a PoStep25-256, a PCB tester can validate the motor driver’s connection to the PCB, ensuring there are no issues with the power delivery or signal routing. Meanwhile, a USB oscilloscope can monitor the signals being sent to the stepper motor, providing real-time data on the performance of the PCB. This combination of testing tools creates a holistic approach to ensuring the success of a project, from initial design to final implementation.

The role of PCB testers extends beyond just development and assembly. They are also crucial during maintenance and repair operations. When a device malfunctions, PCB testers can be used to pinpoint the exact location of the problem, whether it’s a damaged trace, faulty component, or a problem with the overall layout. By using a PCB tester to diagnose the issue, repair technicians can more efficiently identify and fix the fault, reducing downtime and ensuring that the device can be brought back into service quickly.

For engineers and manufacturers working with PoStep25-256 or similar motion control systems, PCB testers are indispensable. These systems often involve complex PCBs that control motor movements, relay signals, and manage high-current power paths. Any issue with the PCB’s electrical integrity can cause significant disruptions, potentially rendering the motion control system unreliable or inoperative. By using PCB testers to ensure the integrity of the PCB, engineers can be confident that their system will function as expected.

As technology advances, the demand for more efficient and reliable PCB testers continues to grow. Innovations in testing technology, such as the introduction of automated optical inspection (AOI) systems, have made PCB testers even more effective. AOI systems use cameras and advanced image processing algorithms to visually inspect PCBs for faults such as component misplacement, soldering issues, or even subtle manufacturing defects. These systems can perform inspections quickly and accurately, further improving the quality control process in PCB production.

In summary, PCB testers play a pivotal role in the electronics industry by ensuring that circuit boards are designed, manufactured, and tested to the highest standards. By identifying potential faults and verifying the integrity of the board before it is integrated into a larger system, PCB testers help prevent costly errors and ensure that electronic devices function reliably. Whether you are working with a simple circuit or a complex system like a PoStep25-256-driven motion control setup, a PCB tester provides the necessary confidence that the board will operate correctly and that your project will be a success.

USB Oscilloscope: A Portable Solution for Accurate Signal Analysis

In electronics, analyzing and troubleshooting signals is a crucial step in ensuring the functionality and reliability of circuits. The USB oscilloscope has emerged as a powerful tool for engineers, technicians, and hobbyists, providing a compact, cost-effective solution for real-time waveform analysis. Unlike traditional oscilloscopes, which can be bulky and expensive, a USB oscilloscope connects to a computer via a USB port, offering the same high-quality signal analysis with the added benefit of portability and ease of use.

A USB oscilloscope serves as a diagnostic tool that captures and displays the voltage of electrical signals over time, producing waveforms that provide insight into the behavior of electronic circuits. These oscilloscopes can analyze a variety of signals, including analog and digital waveforms, by sampling them at high frequencies and displaying the resulting data on a connected computer screen. The portability of a USB oscilloscope makes it an ideal choice for engineers who need to test circuits on-site, troubleshoot devices in the field, or even for educational purposes where space and budget constraints exist.

One of the key advantages of a USB oscilloscope is its versatility and ease of use. With many models offering plug-and-play functionality, users can simply connect the device to their computer, install the necessary software, and start analyzing signals right away. The software that comes with USB oscilloscopes often provides powerful features like automated measurements, signal analysis tools, and data logging, which significantly enhance the user experience. Additionally, most USB oscilloscopes are compatible with various operating systems such as Windows, macOS, and Linux, offering broad flexibility for different users.

In terms of performance, modern USB oscilloscopes are capable of delivering high-resolution waveforms and accurate measurements, often rivaling the performance of traditional bench-top oscilloscopes. For example, many USB oscilloscopes offer bandwidths of 20 MHz to 100 MHz or more, with sampling rates exceeding 1 GS/s (gigasamples per second). These specifications are sufficient for most general-purpose applications, including signal analysis in motor control systems, communication devices, and embedded systems.

A USB oscilloscope is particularly useful in troubleshooting electronic devices, such as systems driven by a PoStep25-256 stepper motor driver. When working with motion control systems, it is crucial to ensure that the signals being sent to the motor are clean, stable, and free of noise. By connecting a USB oscilloscope to the control signals of the PoStep25-256, engineers can monitor the waveform of the step and direction signals in real-time. This helps to identify any irregularities, such as spikes, dips, or oscillations, that might cause erratic motor behavior, which could lead to poor performance or even system failure.

Additionally, the ability of a USB oscilloscope to capture high-frequency signals makes it an essential tool for analyzing high-speed communication protocols like I2C, SPI, or UART. In systems involving communication between microcontrollers and peripheral devices, signal integrity is paramount. With a USB oscilloscope, users can observe the timing and voltage levels of the signals to ensure they meet the required specifications. This capability is particularly important when decoding protocols like I2C, where timing and synchronization are critical to proper data transmission.

Another notable feature of USB oscilloscopes is their portability, which makes them ideal for mobile applications or environments with limited workspace. Unlike traditional oscilloscopes that often require a dedicated bench setup, USB oscilloscopes can easily be taken on the go, allowing users to test and troubleshoot circuits in various locations, whether in the lab, on the factory floor, or out in the field. This portability makes them a valuable tool for engineers working in remote areas or for projects that require testing on-location.

While traditional oscilloscopes are often limited to a fixed set of measurement capabilities, a USB oscilloscope can leverage the power of the host computer to enhance its functionality. Many software packages designed for USB oscilloscopes offer advanced features like frequency spectrum analysis, waveform averaging, or even protocol decoding. These features enable users to gain deeper insights into the behavior of their circuits, troubleshoot complex issues, and ensure the design meets the necessary specifications.

The integration of USB oscilloscopes with other testing tools, such as PCB testers, further improves the diagnostic process. For example, when testing a PCB that incorporates a PoStep25-256 stepper motor driver, a PCB tester can verify the electrical integrity of the board, while the USB oscilloscope can monitor the signals in real-time, ensuring the driver’s performance is stable. This combination of tools provides a comprehensive testing and analysis solution, significantly reducing the time and effort needed for troubleshooting.

In addition to their use in development and testing, USB oscilloscopes are valuable in educational and DIY environments. Their affordability, portability, and user-friendly software make them an excellent choice for students learning about electronics or hobbyists building their own projects. The visual nature of oscilloscopes allows learners to gain an intuitive understanding of how electrical signals behave, fostering a deeper understanding of the underlying principles of electronics.

For manufacturers and developers working on mass-produced products, USB oscilloscopes are also beneficial for quality control and production testing. During the manufacturing process, USB oscilloscopes can be used to verify that each unit meets the required performance standards by testing the electrical signals in real-time. This ensures that products shipped to customers are free from defects and operate as intended.

Despite their smaller form factor and lower cost, USB oscilloscopes offer a range of performance capabilities that make them a viable alternative to traditional benchtop models. As technology continues to improve, newer USB oscilloscopes will likely offer even higher bandwidths, faster sampling rates, and more advanced features, making them even more powerful and versatile for both professional engineers and hobbyists alike.

In summary, USB oscilloscopes have become a critical tool for signal analysis in modern electronics, providing portable, affordable, and high-performance testing capabilities. Their ability to capture and analyze electrical signals, from motor control systems like PoStep25-256 to communication protocols such as I2C, makes them essential for troubleshooting, development, and quality control. The integration of USB oscilloscopes with other diagnostic tools, like PCB testers, ensures a comprehensive testing approach, helping engineers and technicians achieve reliable and accurate results across a wide range of applications. Whether you’re working on a professional project or learning about electronics, a USB oscilloscope is a powerful tool that can significantly enhance your understanding of circuit behavior and system performance.

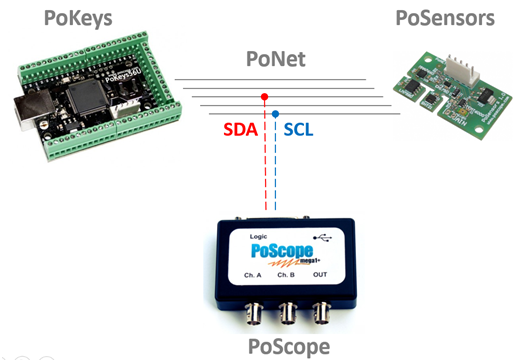

Decoding I2C Protocol: Unlocking the Power of Serial Communication

In the world of embedded systems and electronics, efficient communication between components is essential. One of the most widely used communication protocols is I2C (Inter-Integrated Circuit), a simple, yet powerful protocol that allows multiple devices to communicate with each other using just two wires. The ability to decode and analyze I2C protocol is vital for anyone working with systems that involve microcontrollers, sensors, displays, or other peripheral devices. This chapter explores the I2C protocol, its functionality, and how decoding I2C signals can enhance troubleshooting and system development.

At its core, I2C is a serial communication protocol that allows data to be transferred between a master device (usually a microcontroller or processor) and multiple slave devices (such as sensors, EEPROMs, or motor controllers) over a two-wire bus. These two wires, SCL (clock) and SDA (data), carry the signals that synchronize communication between devices. The protocol is particularly valuable because it supports multi-master and multi-slave configurations, enabling complex systems with many interconnected components to communicate with one another seamlessly.

Decoding I2C protocol refers to the process of interpreting the electrical signals transmitted over the SDA and SCL lines to understand the data being sent between devices. In its raw form, the data transferred in I2C is just a series of high and low voltage levels representing bits of information. However, without proper tools and methods, it’s challenging to understand the meaning of these signals. This is where tools like USB oscilloscopes and logic analyzers come into play. They capture and display the signals, allowing engineers to decode and analyze the data being exchanged between the master and slave devices.

The process of decoding I2C protocol involves examining the timing and structure of the signals to identify key components of the communication. For instance, the SCL line carries the clock signal, which is used to synchronize data transmission between the master and slave devices. The SDA line carries the actual data, with each bit being sent sequentially on the falling edge of the clock signal. In I2C, data is transmitted in the form of 8-bit bytes, followed by an acknowledgment (ACK) bit from the receiving device to confirm that the data was received correctly. Understanding this fundamental structure is essential for decoding the protocol and troubleshooting any issues that may arise.

When I2C communication is working correctly, the signals on the SDA and SCL lines should follow a well-defined timing pattern. However, in many cases, problems such as noise, incorrect voltage levels, or timing errors can cause communication failures. By decoding the I2C protocol and observing the waveforms using a USB oscilloscope or a logic analyzer, engineers can identify where the issue lies. For example, if the SDA line is not properly transitioning between high and low states, it could indicate a faulty connection or a problem with the slave device. Similarly, if the SCL line is not generating the correct clock signal, the communication between devices may become desynchronized, leading to data corruption or loss.

One common issue in I2C communication is when the master device sends a start condition or address byte, but the slave device fails to respond with an acknowledgment (ACK). This can happen for a variety of reasons, such as the slave being in a different state, incorrect addressing, or physical connection problems. Decoding the I2C protocol using a USB oscilloscope allows engineers to visually inspect the timing of the start condition, the address byte, and the ACK response, helping them pinpoint the source of the failure. Once the issue is identified, engineers can correct the problem, whether it’s a connection issue, an incorrect device address, or a software configuration error.

Another challenge in I2C communication is ensuring that data is transmitted without interference from other devices on the bus. Because I2C is a shared bus protocol, all devices on the bus are connected to the same SDA and SCL lines. If there are multiple devices communicating simultaneously, the bus can become congested, leading to data collisions and timing issues. By decoding I2C protocol signals with the help of a USB oscilloscope, engineers can observe the overall traffic on the bus and identify when and where collisions occur. This can provide insights into how the devices are interacting and whether adjustments are needed to improve bus arbitration.

For systems that use the PoStep25-256 stepper motor driver, decoding the I2C protocol can be particularly useful for troubleshooting communication between the motor driver and the microcontroller. In many motion control systems, the PoStep25-256 communicates with a microcontroller over I2C to adjust motor parameters, such as step size, direction, and speed. If the I2C communication fails or is misconfigured, the motor driver may not receive the correct commands, resulting in erratic motor behavior or complete failure. By decoding the I2C protocol with a USB oscilloscope or logic analyzer, engineers can verify that the correct data is being sent to the motor driver and troubleshoot any issues in the communication process.

In addition to troubleshooting, decoding I2C protocol can also be used for system optimization. For example, by analyzing the timing of I2C signals, engineers can ensure that communication is happening at the most efficient speed possible. I2C supports a variety of clock speeds, from standard mode (100 kHz) to high-speed mode (400 kHz), and even higher speeds in some cases. By examining the timing diagrams and ensuring that the SCL line is running at the correct frequency, engineers can optimize data throughput and minimize latency in the system.

The ability to decode I2C protocol also plays a crucial role in reverse engineering and debugging third-party devices. If a developer is working with a device that uses I2C for communication but does not provide detailed documentation, decoding the I2C protocol can help reveal how the device operates and how to interact with it. For instance, by capturing and analyzing the I2C traffic between a microcontroller and an unknown device, developers can figure out the device’s address, command structure, and data formats, enabling them to integrate the device into their own systems.

In conclusion, decoding I2C protocol is an essential skill for anyone working with embedded systems, sensors, or devices that use I2C for communication. By understanding the structure and timing of the I2C signals, engineers can troubleshoot issues, optimize performance, and integrate complex systems with ease. Tools like USB oscilloscopes and logic analyzers are invaluable in this process, enabling users to visually capture and analyze the signals in real-time. Whether you’re working with a PoStep25-256 motor driver, debugging a complex embedded system, or reverse engineering a third-party device, decoding I2C protocol will provide the insights you need to ensure reliable, efficient communication.

Mastering Key Tools for Electronics Development

In the rapidly evolving world of electronics, mastering the essential tools for design, testing, and troubleshooting is crucial for ensuring high-quality, reliable products. This article has explored four critical tools and techniques—PoStep25-256, PCB testers, USB oscilloscopes, and decoding I2C protocol—that form the backbone of modern electronics development. Each of these tools plays a unique role in enhancing the performance, efficiency, and reliability of electronic systems, from initial design to final production.

The PoStep25-256 motor driver, with its precise control over stepper motors, is an integral component in motion control systems. Understanding and utilizing its capabilities ensures the accurate operation of devices ranging from robotics to industrial machinery. Whether designing new motion control systems or troubleshooting existing ones, having a deep understanding of the PoStep25-256 and its integration with the rest of the system is crucial for achieving optimal performance.

PCB testers are equally important, as they allow engineers to validate the integrity of their designs before they move to full-scale production. A PCB tester ensures that the physical layout of a printed circuit board is functional, detecting issues such as open circuits or shorts that could lead to failure. By identifying and addressing these faults early in the development process, engineers can save time, reduce costs, and enhance the reliability of their designs.

The USB oscilloscope, with its portable and user-friendly design, revolutionizes how signals are analyzed in the field. Whether you’re troubleshooting a PoStep25-256-driven motor system or inspecting a communication bus like I2C, a USB oscilloscope provides the real-time insights needed to diagnose issues effectively. Its ease of use, coupled with powerful software tools, has made it an indispensable tool for both professionals and hobbyists alike. The portability of USB oscilloscopes further allows for on-the-go testing, making them invaluable in situations where space and convenience are at a premium.

Finally, decoding I2C protocol is fundamental for understanding how different devices communicate in embedded systems. Whether working with sensors, microcontrollers, or motor drivers like the PoStep25-256, decoding I2C signals gives engineers the ability to ensure data is transmitted correctly and troubleshoot any communication errors. Tools like USB oscilloscopes and logic analyzers make this process easier by capturing and displaying the communication between devices, allowing engineers to pinpoint issues and optimize performance.

Together, these four tools—PoStep25-256, PCB testers, USB oscilloscopes, and the ability to decode I2C protocol—empower engineers to create more reliable, efficient, and innovative electronic systems. The integration of these tools into the development process ensures that designs are not only functional but also optimized for performance and durability. As technology continues to advance, the role of these diagnostic tools will only become more critical, helping engineers and technicians navigate the complexities of modern electronics with precision and confidence.

In conclusion, understanding how to effectively use these tools and techniques is essential for anyone involved in the development of electronic systems. Whether you’re designing motion control systems, testing PCBs, analyzing signals, or decoding communication protocols, mastering these skills will provide the foundation for successful projects and innovative solutions in the world of electronics.